A safer, easier, more efficient way to run cables on above ground pipelines.

Brief History of Cables on Pipes

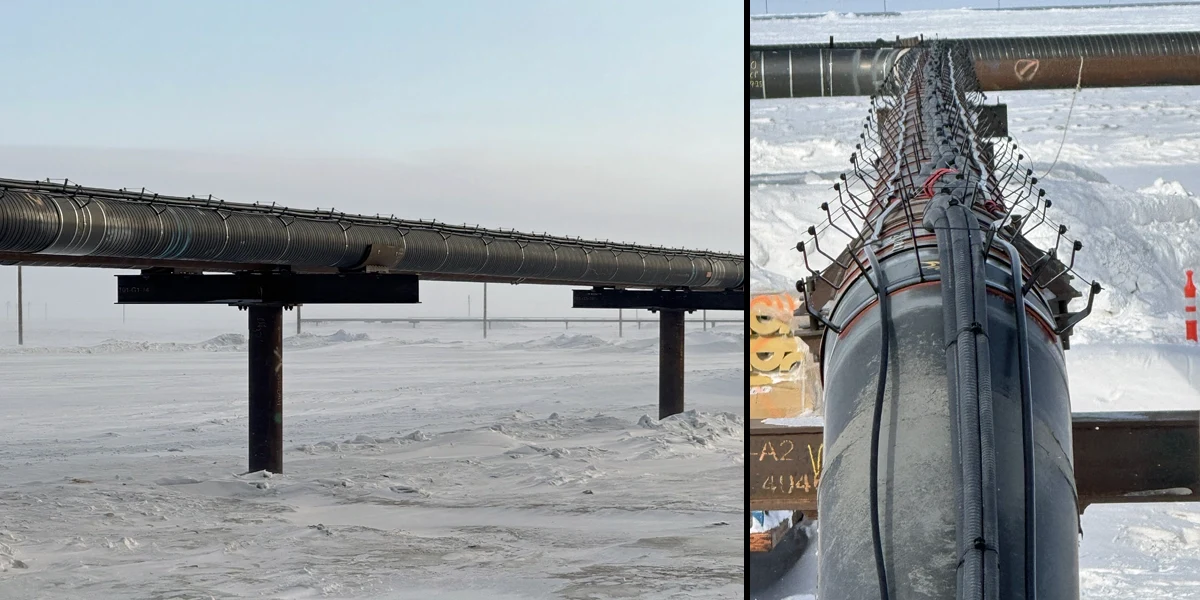

Susitna Power Solutions pipeline cable management system operates similarly to pipeline systems used in the North Slope oil fields. Pipelines are engineered to accommodate expansion and contraction caused by significant temperature variations throughout the year, which can range from -75 to 90 degrees Fahrenheit. Because steel pipes expand when heated and contract when cooled, a system was developed to allow for these changes. This arrangement features UHMW-lined pipe saddles, expansion loops, pipe anchors, etc. Additionally, some pipeline installations require power, communications, and control cables to be routed alongside the pipes. When pipes run to the same locations, utilizing existing or new infrastructure for cable routing is a practical solution. As a result, banding cables directly to the pipe became a common practice.

Complications In This Extreme Environment

However, while steel pipes expand and contract seasonally, cables do not change much in length, which can result in cables detaching and increased stress on the cables as well as the pipes.

Consequently, the steel messenger cable system employing rings to support power and communications cables was implemented. While effective, this approach presents certain challenges.

Typically, it is constructed beneath the horizontal support members (HSMs), resulting in the cables being suspended approximately two feet below the piping.

This configuration can lead to ground clearance concerns, particularly in years with substantial snowfall.

Additionally, this method incurs increased costs due to the requirement for deeper excavation, greater volumes of slurry, and supplemental steel materials necessary to achieve adequate elevation for HSMs set at two feet or higher.

Another limitation is that only one large power cable can be accommodated per steel messenger; if additional cable is required, an extra messenger cable must be installed, further increasing expenses.

The Solution

These methods are valuable, particularly in the challenging conditions of the North Slope. However, the Susitna Power Solutions cable management system provides an enhanced approach with a single-installation method. The patented cable brackets can accommodate multiple large-diameter cables as well as various communications and control cables.

This system operates similarly to a pipeline: as the pipe heats and expands, cable slack stored within the pipe’s expansion loops is deployed; when the pipe cools and contracts, the cable retracts into the slack storage in the expansion loops.

This cable management system offers numerous advantages, including enhanced safety and operational efficiency.

Efficiency Through Safety, Organization, and Risk Management

Following the attachment of brackets to the pipe, cables are generally installed using heavy equipment that securely places them into the brackets. Susitna Power Solutions new cable management system eliminates the need for personnel to approach machinery, unlike conventional methods where employees must enter hazardous zones to manually hang or strap cables—thereby increasing the risk of accidents. Consequently, this system substantially reduces the risk of incidents involving employees and equipment.

Positioning cables above the pipe mitigates concerns regarding ground clearance and helps prevent potential issues for both the public and wildlife populations.

Additionally, the system improves workplace organization by ensuring cables remain neatly arranged and unobtrusive, which minimizes hazards and fosters a cleaner, more orderly environment.

Such organization not only supports safety initiatives but also streamlines routine inspections and maintenance activities. With positioning the cables on top of the pipe, visual inspections of the cables by drone become simplified.

Due to the substantially more efficient installation of brackets compared to traditional banding or messenger techniques, this method results in lower labor requirements and reduced equipment costs during installation and maintenance activities.

Operational Efficiencies

The design also allows for the addition, replacement, or relocation of cables without disrupting those already in place within the cable management system.

Finally, with brackets and cables mounted on top of the pipe, shorter pilings, shallower drilling, less slurry required, and being lower in elevation further enhancing overall project efficiency.

To order or for more information on this new cable management system, contact us.

If you’re looking for a safer, easier, more efficient way to run cables on above ground pipelines, you’ve found it!

The Susitna Power Solutions pipeline cable management system operates similarly to pipeline systems used in the North Slope oil fields. Pipelines are engineered to accommodate expansion and contraction caused by significant temperature variations throughout the year, which can range from -75 to 90 degrees Fahrenheit. Because steel pipes expand when heated and contract when cooled, a system was developed to allow for these changes.

The Susitna Power Solutions pipeline cable management system operates similarly to pipeline systems used in the North Slope oil fields. Pipelines are engineered to accommodate expansion and contraction caused by significant temperature variations throughout the year, which can range from -75 to 90 degrees Fahrenheit. Because steel pipes expand when heated and contract when cooled, a system was developed to allow for these changes.

This arrangement features UHMW-lined pipe saddles, expansion loops, and pipe anchors. Additionally, some pipeline installations require power, communications, and control cables to be routed alongside the pipes. When pipes run to the same locations, utilizing existing or new infrastructure for cable routing is a practical solution. As a result, banding cables directly to the pipe became a common practice. However, while steel pipes expand and contract seasonally, cables do not change much in length, which can result in cables detaching and increased stress on the cables as well as the pipes.

Consequently, the steel messenger cable system employing rings to support power and communications cables was implemented. While effective, this approach presents certain challenges. Typically, it is constructed beneath the horizontal support members (HSMs), resulting in the cables being suspended approximately two feet below the piping. This configuration can lead to ground clearance concerns, particularly in years with substantial snowfall.

Additionally, this method incurs increased costs due to the requirement for deeper excavation, greater volumes of slurry, and supplemental steel materials necessary to achieve adequate elevation for HSMs set at two feet or higher. Another limitation is that only one large power cable can be accommodated per steel messenger; if additional cable is required, an extra messenger cable must be installed, further increasing expenses.

Cable Management Tough Enough For The North Slope

These methods are valuable, particularly in the challenging conditions of the North Slope. However, the Susitna Power Solutions cable management system provides an enhanced approach with a single-installation method. The patented cable brackets support multiple large-diameter cables as well as various communications and control cables. This system operates similarly to a pipeline: as the pipe heats and expands, cable slack stored within the pipe’s expansion loops is deployed; when the pipe cools and contracts, the cable retracts into the slack storage in the expansion loops.

This cable management system offers numerous advantages, including enhanced safety and operational efficiency.

Following the attachment of brackets to the pipe, cables are generally installed using heavy equipment that securely places them into the brackets. This new system eliminates the need for personnel to approach machinery, unlike conventional methods where employees must enter hazardous zones to manually hang and strap cables—thereby increasing the risk of accidents. Consequently, this system substantially reduces the risk of incidents involving employees and equipment.

Positioning cables above the pipe mitigates concerns regarding ground clearance and helps prevent potential issues for both the public and wildlife populations.

Additionally, the system improves workplace organization by ensuring cables remain neatly arranged and unobtrusive, which minimizes hazards and fosters a cleaner, more orderly environment. Such organization not only supports safety initiatives but also streamlines routine inspections and maintenance activities. With positioning the cables on top of the pipe, inspections of the cables by drone become simplified.

Fast Efficient Cable Management Systems That Save Time And Money

Due to the substantially more efficient installation of brackets compared to traditional banding or messenger techniques, this method results in lower labor requirements and reduced equipment costs during installation and maintenance activities.

The design also allows for the addition, replacement, or relocation of cables without disrupting those already in place within the cable management system.

Finally, with brackets and cables mounted on top of the pipe, shorter pilings, shallower drilling, and less slurry are required, further enhancing overall project efficiency.

To order or for more information on this new cable management system, contact us.